The Ultimate Guide to Selecting a Jaw Crusher for Mining Operations

In the demanding world of mining, where profitability hinges on efficiency and reliability, the primary crushing stage is arguably the most critical. The jaw crusher stands as the undisputed workhorse of this stage, designed to handle the massive, unrefined feed material from the quarry face and reduce it to a manageable size for downstream processes. Selecting the right jaw crusher for mining is not just an equipment choice; it's a fundamental business decision that impacts productivity, operational costs, and overall project viability. This guide delves into the essentials of leveraging a jaw crusher in a mining context.

Why a Jaw Crusher is Ideal for Mining Applications

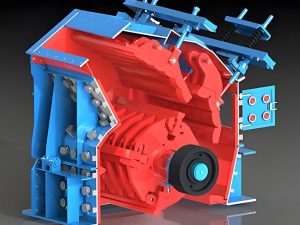

Jaw crushers are uniquely suited for the harsh conditions of mining due to their robust design and simple but effective operating principle. Their ability to process incredibly hard and abrasive materials—from granite and basalt to iron ore and copper ore—makes them indispensable. The key to their effectiveness lies in the powerful mechanical compression action, where two rugged manganese steel jaws crush the material against a stationary plate. This method provides high throughput and excellent reduction ratios, often as high as 6:1, meaning the crusher can accept large feed material and output a consistently sized product, ready for the next stage of crushing. Their rugged construction ensures continuous operation under heavy loads with minimal downtime.

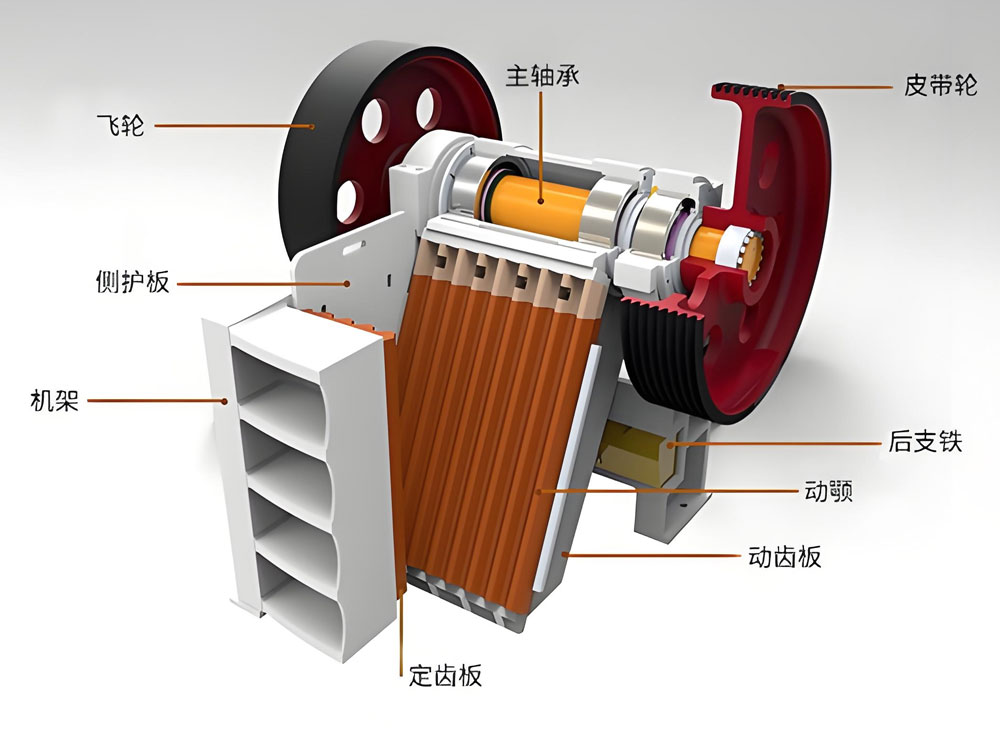

Key Features of a Heavy-Duty Mining Jaw Crusher

When evaluating a jaw crusher for a mining operation, several heavy-duty features are non-negotiable:

Robust Frame: The frame is constructed from high-quality steel plate, often with reinforced ribs to withstand the immense stress and cyclic loading.

Manganese Steel Jaws: The crushing jaws are made from hardened manganese steel, known for its exceptional wear resistance and ability to work-harden under pressure, extending service life.

Spherical Roller Bearings: Large, self-aligning spherical roller bearings are used to handle heavy radial and thrust loads, ensuring smooth operation and long bearing life.

Hydraulic Adjustment: Modern mining jaw crushers feature hydraulic adjustment systems for quickly and safely changing the closed-side setting (CSS), which determines the product size. This eliminates the need for manual shims.

Toggle System: A robust toggle plate and seat are designed to act as a safety mechanism. In the event of an uncrushable object (like tramp metal), the toggle plate is designed to break, protecting the crusher from catastrophic damage.

Technical Specifications and Performance Parameters

Understanding the technical specifications is crucial for matching the crusher to your mine's output goals and feed material characteristics. Below is a table outlining typical parameters for a large-capacity mining jaw crusher.

Parameter Description & Typical Specification

Feed Opening 1,500 x 1,200 mm (59" x 47") - Allows for processing large boulders.

Max. Feed Size Up to 1,200 mm (47") in diameter.

Closed Side Setting (CSS) Range 150 - 300 mm (6" - 12") - Adjustable based on required product size.

Capacity 500 - 1,500 tonnes per hour (TPH) - Varies based on material type, CSS, and feed gradation.

Power Requirement 200 - 400 kW (250 - 500 HP) - Driven by a high-torque electric motor.

Total Weight Approximately 120,000 kg (265,000 lbs) - Indicative of its robust construction.

Crushing Principle Overhead Eccentric Single Toggle or Double Toggle design for high efficiency.

Note: These are example specifications. Actual models will vary in size and capacity.

A Real-World Production Case Study: Granite Quarry, Southeast Asia

Challenge: A large granite quarry in Southeast Asia was facing bottlenecks in its primary crushing circuit. Their existing setup could not handle the required increased production volume of 2,000 TPH of aggregate. The abrasive nature of the granite was also causing excessive wear part consumption and unplanned downtime.

Solution: The operation invested in a new, high-capacity jaw crusher specifically engineered for hard rock mining. The crusher was selected for its large feed opening, which accommodated the biggest granite boulders from their blast patterns, and its superior wear resistance.

Results:

Throughput Achieved: Consistently exceeded the target, processing over 2,200 TPH of granite.

Availability: Crusher availability reached 95%, thanks to a reliable design and easy maintenance access.

Operational Cost Reduction: The use of advanced manganese steel jaws increased wear life by over 30%, significantly reducing downtime for part changes and lowering cost-per-tonne crushed.

Product Quality: The adjustable hydraulic settings allowed operators to easily produce a well-shaped, optimally sized product for the secondary cone crushers, improving the overall efficiency of the entire crushing plant.

Maintenance and Safety Best Practices

Maximizing the lifespan and safe operation of a mining jaw crusher requires a disciplined approach.

Regular Inspection: Conduct daily visual checks for wear and leaks. Schedule regular shutdowns to inspect jaw dies, cheek plates, and the toggle system.

Lubrication: Follow a strict lubrication schedule for the bearings and the toggle seat. Contaminated grease is a primary cause of bearing failure.

Wear Part Management: Monitor wear part thickness and plan replacements well in advance to avoid unexpected failures. Rotating and swapping jaws can optimize their service life.

Safety First: Always observe lock-out/tag-out (LOTO) procedures before performing any maintenance or clearing a blockage. Never enter the crushing chamber or perform work on the equipment without ensuring all energy sources are isolated.

Making the Right Investment for Your Mine

Choosing a jaw crusher is a long-term investment. Beyond the initial purchase price, consider the total cost of ownership, which includes energy consumption, wear part costs, maintenance labor, and expected availability. The right jaw crusher for your mining operation will be one that offers not just the required capacity, but also the durability to withstand your specific material conditions, coupled with design features that promote safety and ease of maintenance. By carefully analyzing your production needs and partnering with a reliable supplier, you can ensure your primary crusher becomes a cornerstone of your mining operation's success for years to come.