HP200 Cone Crusher for sale

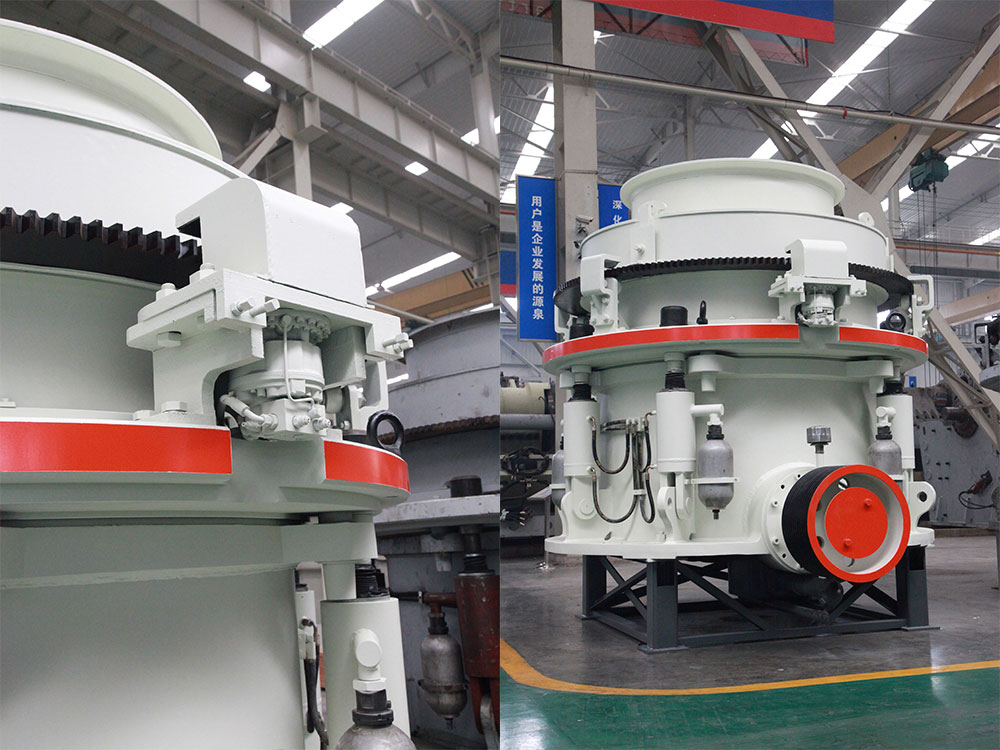

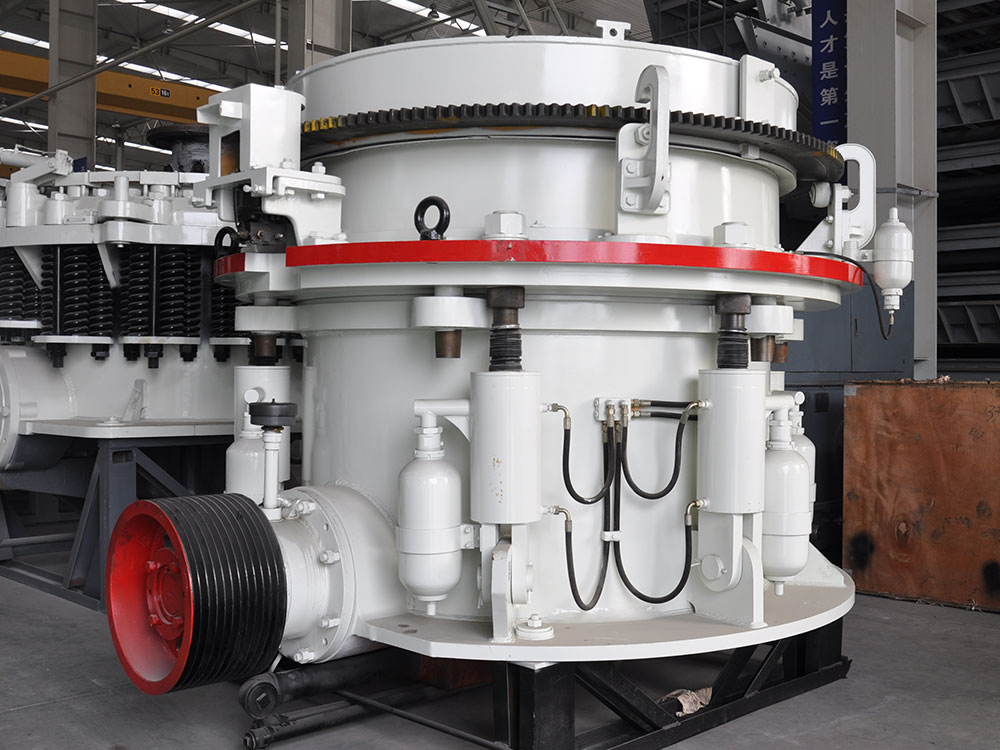

HP200 cone crusher is a highly respected equipment in the global mining, construction and aggregate industries, and is widely praised for its excellent crushing performance, reliability and versatility.The working principle of HP200 cone crusher is based on the combined effects of extrusion, impact and friction. Driven by the hydraulic system, the movable cone performs periodic reciprocating motion, and the gap between it and the fixed cone is constantly changing. After the material enters the crushing chamber, it is squeezed, impacted and frictional by the movable cone and the fixed cone, and is gradually crushed into the required particle size.

HP200 Cone Crusher for sale working principle

Frame: Provides support for the entire crusher.

Moving cone: Conical, driven by the hydraulic system, produces relative movement with the fixed cone to achieve material crushing.

Fixed cone: Fixed, together with the moving cone, it forms a crushing chamber.

Crushing chamber: Crushing chambers of different shapes and sizes can be replaced according to different materials and crushing requirements.

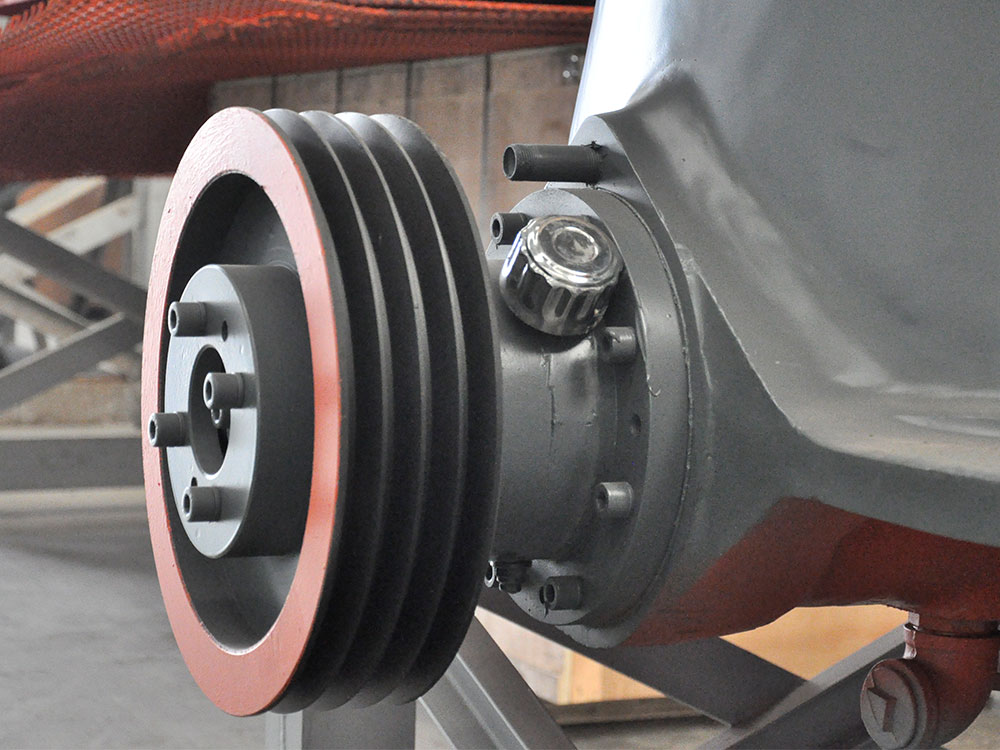

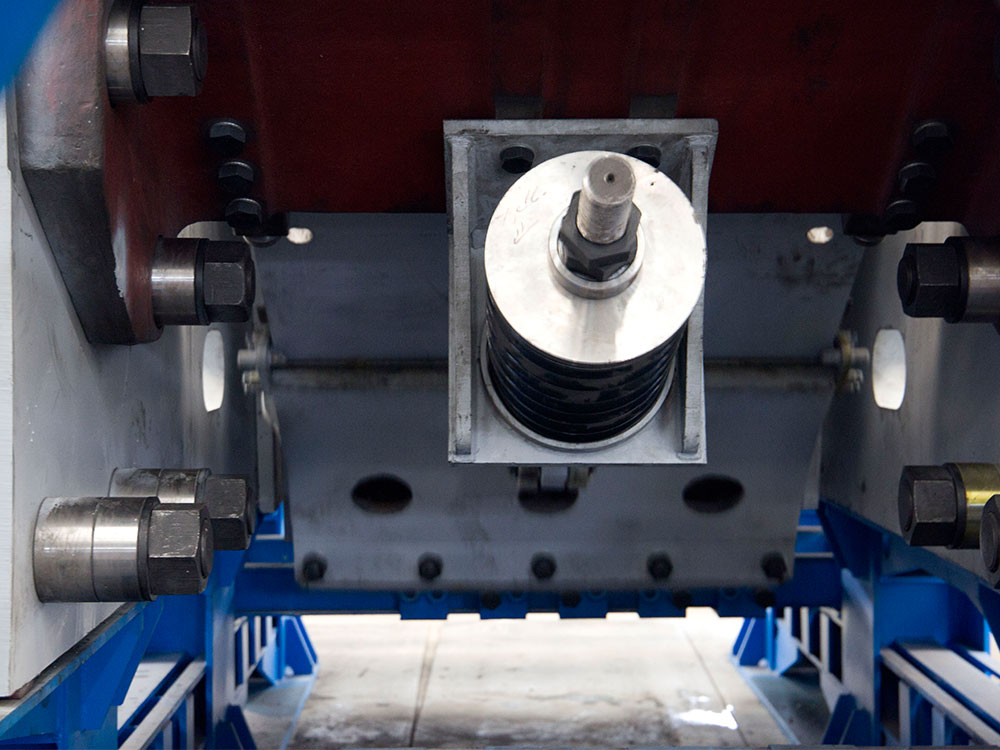

Hydraulic system: Provides driving force and adjustment for the moving cone, and controls the opening size of the crushing chamber.

Lubrication system: Ensures lubrication of all moving parts and extends the service life of the equipment.

Control system: Realizes automatic control and monitoring of the crusher.

Eccentric motion: The moving cone is driven by a hydraulic system and rotates around an eccentric shaft to produce periodic reciprocating motion.

Formation of the crushing chamber: The movement of the moving cone causes the gap between the moving cone and the fixed cone to change continuously, forming a constantly changing crushing chamber.

Material crushing: After the material enters the crushing chamber, it is squeezed, impacted and rubbed by the moving cone and the fixed cone, and is gradually crushed into the required particle size.

Product discharge: The crushed material is discharged from the lower part of the crushing chamber.

HP200 Cone Crusher for sale Advantages

Advanced crushing chamber design

HP200 adopts an optimized crushing chamber design, which realizes efficient crushing by finely simulating the movement trajectory and crushing mode of the material in the crushing chamber.

Precise particle size control

By adjusting the hydraulic system and replacing different types of crushing chambers, the particle size of the product can be accurately controlled to meet the needs of different users.

Easy replacement of wearing parts

The equipment adopts a modular design, which is easy to disassemble and repair. The replacement of wearing parts is simple and quick, reducing downtime.

Intelligent control system

Equipped with advanced intelligent control system, it realizes automated operation and remote monitoring, thus improving production efficiency.

Low maintenance cost and long service life

The use of high-quality materials and advanced technology prolongs the service life of the equipment. It is easy to maintain and reduces maintenance costs.

HP200 Cone Crusher for sale technical parameter

| diameter | 900mm | Feed size | ≤145mm |

| power | 160kw | Discharge size | 10-22mm |

| Yield | 81-250t/hHost Weight | Host Weight | 11t |

HP200 Cone Crusher for sale Case Analysis

This project uses HP200 cone crusher to produce roadbed materials. The tight construction schedule of the expressway puts higher requirements on the continuous operation performance of the equipment. HP200 cone crusher has high crushing efficiency and good product quality, which provides guarantee for the smooth construction of the expressway.

"The crushing efficiency of the HP200 crusher is very high, far exceeding our expectations."

"The particle size of the product crushed by the HP200 is very uniform, which provides great convenience for our subsequent processing."

"The HP200 has a high degree of automation and is easy to operate, which greatly reduces the error of manual operation."

"The maintenance cost of the HP200 is relatively low, and the reliability of the equipment is also very good."